Fully Automated Parking Systems

Automated vehicle storage and retrieval systems (AVSRS), also known as Automated Parking Systems (APS) or Automated Parking Garages (APGs) use robotic storage/retrieval devices that are controlled by integrated software technology to park and return vehicles from centralized loading bays. Vehicles are stored in compact storage vaults where public access is not permitted.

Automated Parking Systems are entirely automated: vehicles are parked in convenient loading bays, scanned, and transferred via robotic devices that do not require human intervention. Automated parking technology enables multiple devices to operate simultaneously to store and retrieve vehicles in multiple-rack structures both vertically and horizontally.

Automated Parking Systems consist of various combinations of components including robotic devices, turntables, shuttles, dollies, and lifts to transfer vehicles to and from the storage vault. Vehicles can be transferred with or without the use of trays or pallets.

AGV Automated Parking System

The Automated Guided Vehicle (AGV) automated parking system consists of free-roaming, battery-operated, omnidirectional units that use traffic management software, markers, vision systems, and lasers for self-guidance to manage the automated storage and retrieval of vehicles.

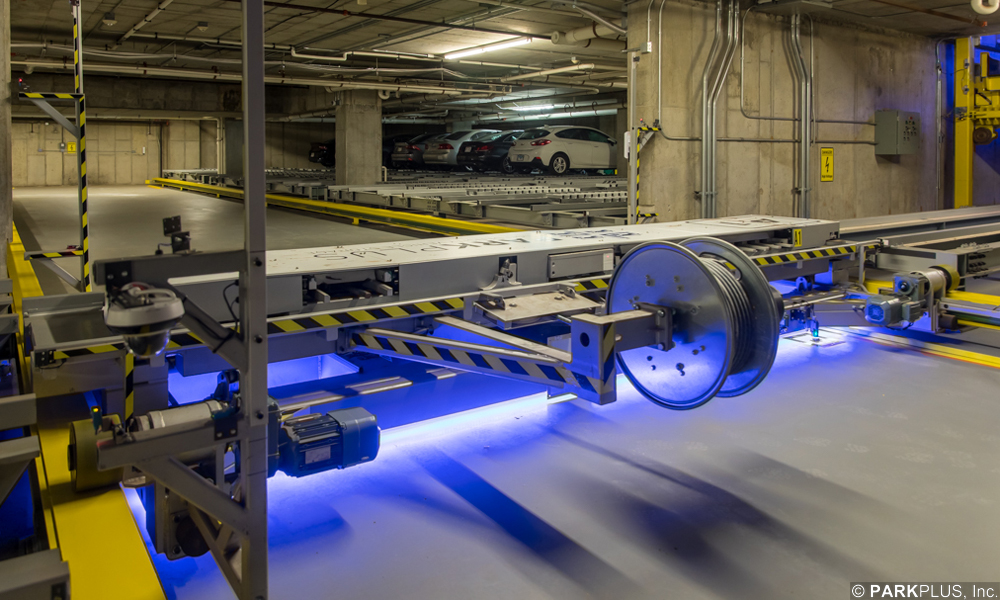

Designed and manufactured in the USA, the PARKPLUS Automated Guided Vehicle parking system has revolutionized high-density vehicle storage and retrieval systems, transformed the parking experience and provided efficient, sustainable and cost-effective parking solutions.

Many equipment variations exist between manufacturers of AGV parking systems, but the general principles remain the same. The most common differences between them occur in their proprietary handling systems, namely pallet, pincer, or comb methods.

Pallet: Vehicle is parked on a tray or platform.

Pincer: Pincer mechanism grabs vehicle by the tires.

Comb: Finger grid mechanism; vehicle lifted from underside of tires.

Rack & Rail Automated Parking System

The Rack and Rail automated parking system consists of fixed-rail devices for vertical and horizontal transfers of vehicles on a grid.

Many equipment variations exist between manufacturers of rack and rail parking systems, but the most common differences between them again occur in their handling systems being either pallet, pincer, or comb methods.

PARKPLUS robotic shuttle for automated Rack and Rail parking system. The Rack and Rail grid system provides regular parking configuration using programmable logic controller software and simple, robust technology. Rack and Rail system is EV-compatible and remote-monitored 24/7.

For all handling system methods of movement, vertical lifting devices are fixed at points along the transfer aisles. Transfer aisles may be open atriums or enclosed floors. Turntables may also be used to present the vehicles face-out for convenience.

###

This content is part of The American Institute of Architects (AIA) and U.S. Green Building Council (USGBC)-accredited course, Introduction to High-Density Parking Systems. Take the course online or register for/request one of our webinars to learn more and earn continuing education points.

844-472-7575

844-472-7575