Building codes: Currently there is no national standard building code specific to automated and mechanical parking systems. Permitting requirements are determined at the local level based on the type and size of the parking system. Review of these systems is similar to steel buildings and S-2 occupancies (low hazard storage). Project planners must always check with the authority having jurisdiction (AHJ) for specific requirements. Each municipality adopts its own set of guidelines and standards for occupancy type, building code requirements, planning requirements, and fire protection requirements.

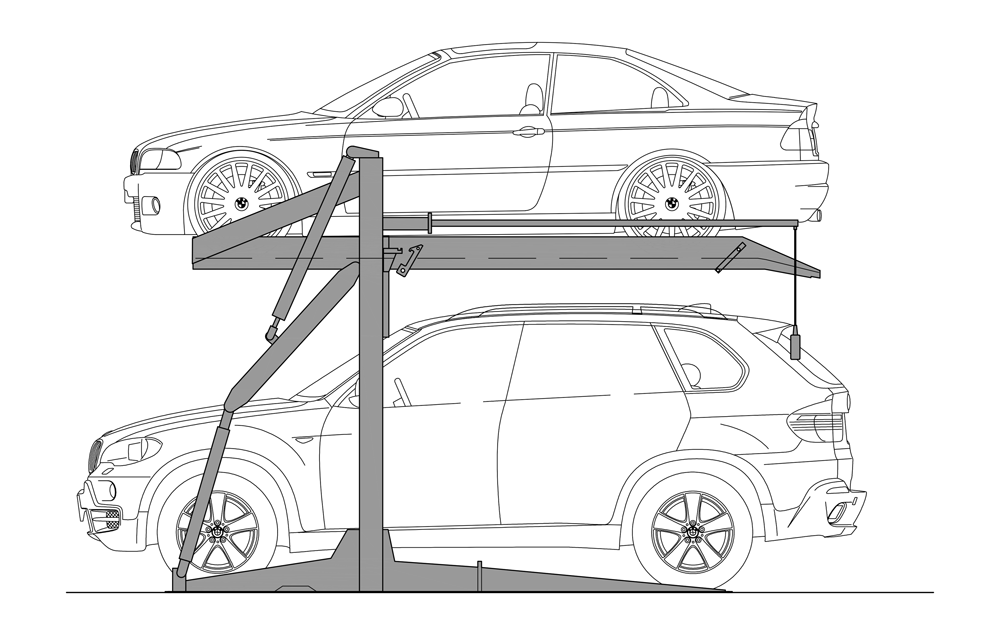

The IBC (International Building Code) and other codes address some general aspects of automated and mechanical parking, but most municipalities find it difficult to fit the vast variety of system types into their current codes. Many cities treat two-level systems that raise only one car between primary supporting members as equipment, but all other systems supporting two or more cars are reviewed seismically as nonbuilding structures.

The Automotive Lift Institute (ALI) has been authorized by American National Standards Institute (ANSI) to develop a national standard for mechanical car stackers similar to the ANSI/ALI ALCTV, “Standard for Automotive Lifts – Safety Requirements for Construction, Testing, and Validation.” High-density parking systems should conform to the IBC, local building codes, AISC (American Institute of Steel Construction) and ASCE (American Society of Civil Engineers) requirements, and ASTM standards as applicable.

Zoning and planning codes: These codes dictate where automated and mechanical parking systems can be used and special requirements for screening, noise isolation, and proximity to other sensitive operations. Some AHJ limit the usage of these systems to specific applications. Many zoning codes dictate the size and type of parking stalls required for different uses. These stall sizes should be considered when determining the vehicle envelope (see below) criteria for a project. Designers should check with local AHJ for parking lot design criteria. Note: high-density parking systems can sometimes be considered as tandem parking; an AHJ may not allow tandem parking for certain uses.

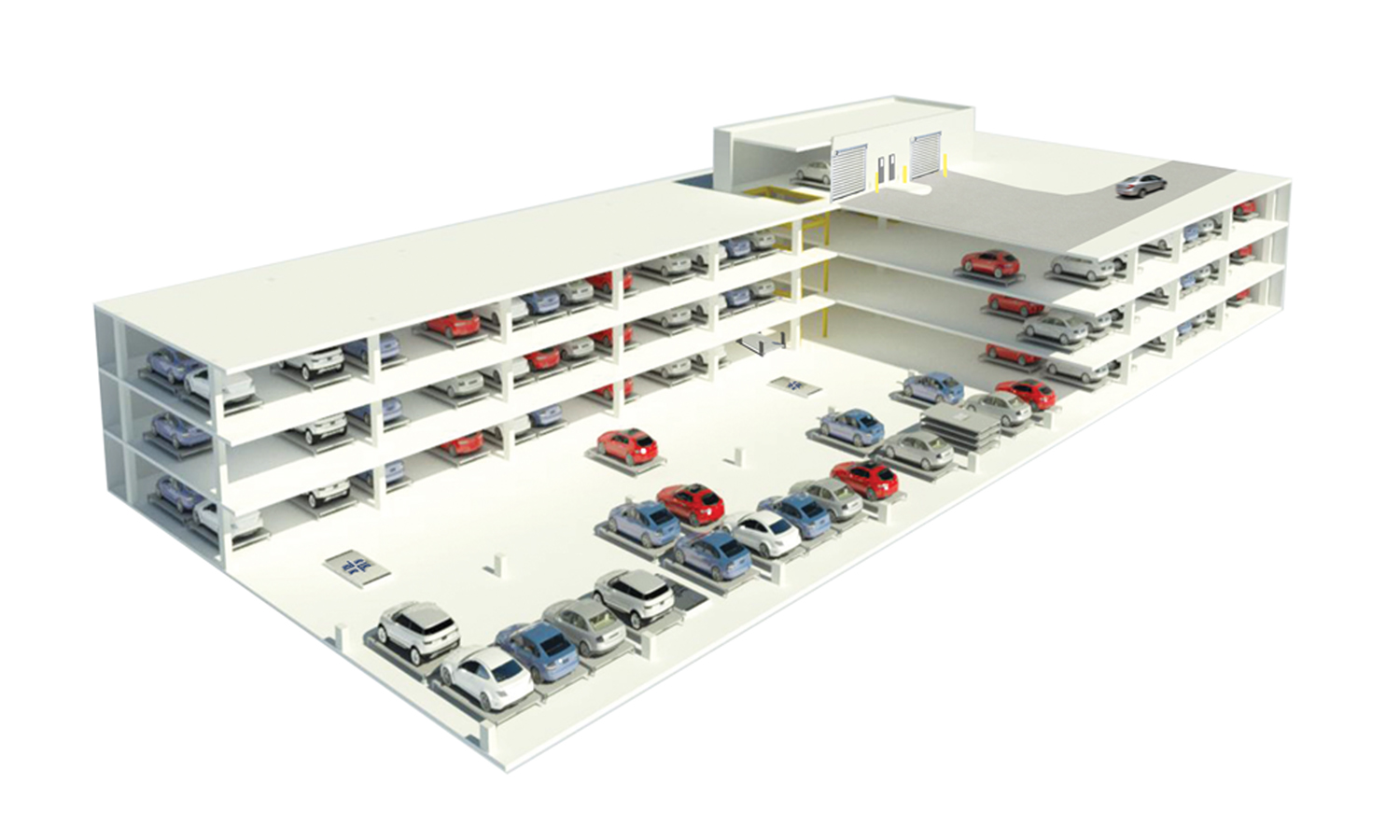

Vehicle envelope: The vehicle envelope is the three-dimensional volume that the system must accommodate, and which vehicles will fit within that 3D envelope. For example, the vehicle envelope for a van-sized vehicle could be interpreted to be 9′-0″ wide x 18′-0″ long x 8′-2″ tall. The City of Los Angeles defines the vehicle envelope of a high-density parking system for standard-sized vehicles as being 8′-0″ wide x 18′-0″ long x 7′-0″ tall, and compact-sized vehicles as being 7′-0″ wide x 15′-0″ long x 6′-0″ tall.

An architect/designer must consider both the footprint and volumetric constraints when determining the allowable number of standard and compact stalls. Each municipality may have its own requirements. Architects should develop a parking program prior to starting the design as this will potentially affect the overall floor-to-floor height of the parking system.

This content is part of The American Institute of Architects (AIA) and U.S. Green Building Council (USGBC)-accredited course, Introduction to High-Density Parking Systems. Take the course online or register for/request one of our webinars to learn more and earn continuing education points.

844-472-7575

844-472-7575